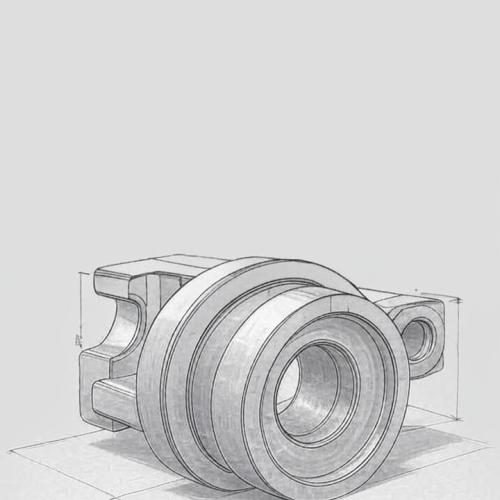

Branch Manufacturing, located in North Branch, MN, leverages advanced CAD drawing capabilities to ensure high-quality production in its 66,000 sq. ft. ISO 9001-certified facility. Since 1952, the company has utilized VISI for precise 2D and 3D drafting, supporting complex processes such as large and small draw operations, stage tooling, and progressive die design. Their quality assurance program integrates sophisticated CAD software with CMM and Faro arm laser scanning to verify design accuracy and compliance with stringent standards. This enables Branch Manufacturing to deliver precise, error-free designs for manufacturing, ensuring rapid turnaround and just-in-time delivery while maintaining excellence in industries like automotive, aerospace, and industrial manufacturing.

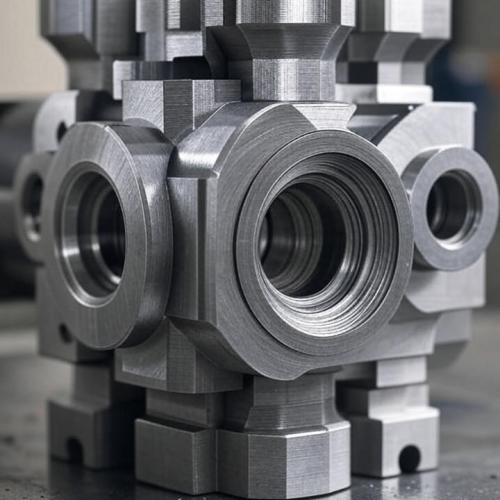

Branch Manufacturing, located at 6420 Pine Street, North Branch, MN, has been a trusted provider of precision CNC machining services since 1952, operating from a 66,000-square-foot facility less than an hour north of the Twin Cities. Equipped with advanced technological equipment, the company specializes in delivering high-quality machined parts with a focus on rapid turnaround and just-in-time delivery to meet customer needs. Their CNC machining capabilities support a variety of industries, leveraging modern production methods to ensure precision and efficiency. Branch Manufacturing emphasizes avid customer service, utilizing state-of-the-art machinery and skilled craftsmanship to produce reliable components, making them a competitive choice for manufacturing solutions in Minnesota.

Branch Manufacturing Company, located in North Branch, MN, is an ISO 9001 certified job shop with robust high tolerance quality assurance capabilities, leveraging advanced technologies to ensure precision in metal fabrication. Equipped with state-of-the-art tools like CMM (Coordinate Measuring Machine) and Faro arm laser scanning, the company maintains stringent quality control for complex manufacturing processes, including large and small draw operations, stage tooling, and progressive dies. Their quality department ensures parts meet tolerances as tight as +/-0.0005 inches, catering to industries such as aerospace, automotive, and medical, with additional services like degreasing, deburring, and plating to enhance product reliability. With over 70 years of experience and a 66,000-square-foot facility featuring 750-ton hydraulic and 600-ton mechanical presses, laser cutting, and 8-axis press brakes, Branch Manufacturing delivers consistent, high-quality results supported by a skilled team and comprehensive quality management systems.

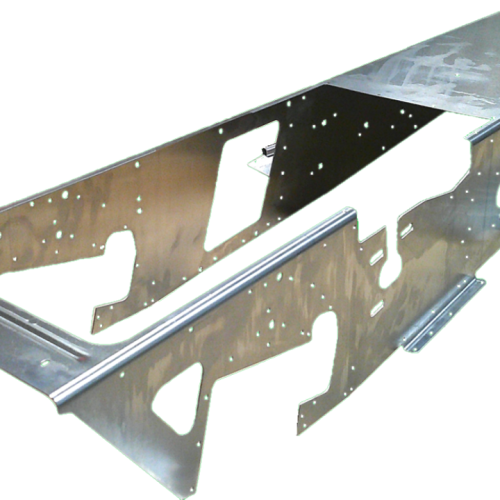

Branch Manufacturing Company, located at 6420 Pine Street, North Branch, MN, specializes in precision laser cutting as part of its comprehensive metal fabrication services. Operating from a 60,000-square-foot facility since 1952, the company leverages advanced CNC laser cutting technology to deliver high-quality, custom metal parts with intricate designs and complex geometries. Their capabilities include cutting various metals, such as steel, stainless steel, and aluminum, catering to industries like automotive, aerospace, and construction. With a focus on rapid turnaround, just-in-time delivery, and stringent quality control, Branch Manufacturing ensures precise, efficient, and reliable laser cutting solutions tailored to meet diverse client needs.

Branch Manufacturing Company, located in North Branch, MN, is a well-established firm founded in 1952, specializing in precision metal stamping and deep draw forming. With a focus on large draw operations and progressive dies, the company leverages advanced technologies such as computer-aided design/manufacturing (CAD/CAM) systems, laser cutting, wire EDM, and Sheffield measurement Cordax RM-50 to produce high-quality components. Their capabilities include grinding, metal stamping, and sheet metal fabrication, supported by state-of-the-art equipment like the Okamoto linear precision surface grinder and ELB Optimal Series NC surface grinder. Serving industries such as automotive, consumer goods, and heavy equipment, Branch Manufacturing caters to clients like Arctic Cat, Toro Company, and Polaris, delivering custom solutions with ISO 9001 certification to ensure quality and precision in their deep drawn and stamped metal products.

Summary of Metal Types at Branch Manufacturing Branch Manufacturing Company, located in North Branch, Minnesota, specializes in working with a variety of metals to meet diverse fabrication needs. Their capabilities include handling stainless steel, aluminum, and carbon steel, utilizing advanced techniques such as large draw operations, progressive dies, laser cutting, and sheet metal fabrication. With a focus on precision and quality, they cater to industries requiring custom metal components, ensuring versatility in processing different metal types to produce high-quality parts and assemblies.

Branch Manufacturing, located at 6420 Pine Street, North Branch, Minnesota, operates a 60,000-square-foot production facility specializing in advanced sheet metal forming since 1952. The company leverages state-of-the-art technology and equipment to deliver precision-crafted sheet metal components, offering services such as shearing, laser cutting, punching, forming, welding, and product assembly. With a focus on rapid turnaround and just-in-time delivery, Branch Manufacturing caters to diverse industries, providing high-quality, custom solutions tailored to meet stringent customer requirements. Their commitment to innovative production methods and exceptional customer service ensures efficient, cost-effective manufacturing for both small and large-scale projects.