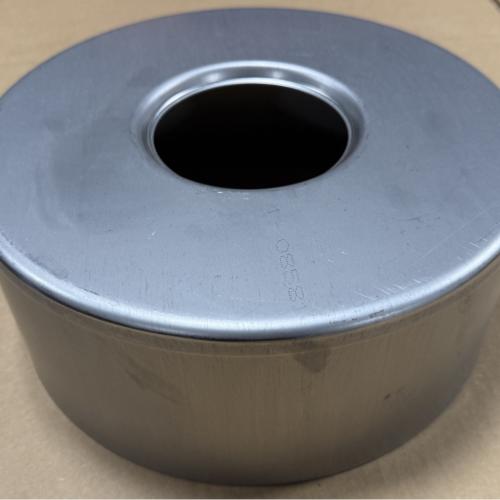

Branch Manufacturing provides expert deep draw metal stamping services, specializing in the production of high-quality drawn parts and stampings for a variety of applications. With a state-of-the-art press room featuring up to 750-ton capacity and hydraulic presses ranging from 300 to 750 tons, they can handle materials up to 1/4" thick and draw large parts up to 12" deep, supporting both short and long production runs. Their in-house capabilities ensure precise, efficient fabrication, including multiple operations in a single press, blanking, progressive tooling, and additional finishing like deburring and spot welding.

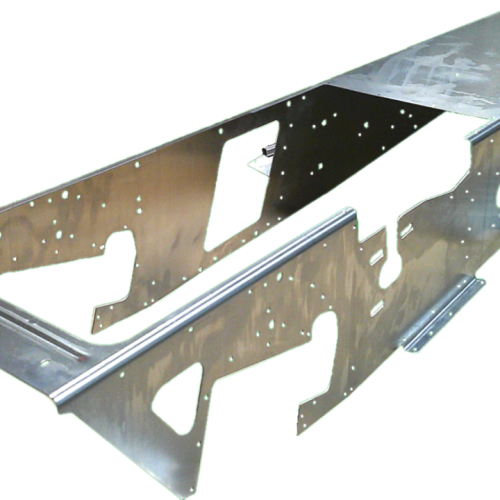

Branch Manufacturing Company, a family-owned business founded in 1952 and based in North Branch, Minnesota, specializes in metal stamping, tooling, and fabrication services from its 66,000-square-foot facility. As part of its offerings, Branch provides advanced laser cutting services using Strippit lasers integrated with CAD/CAM systems like KeyCreator and Multi-Punch, enabling precise cuts on materials up to 1/4" thick and sheets sized 48" x 96". This service excels in short-run productions by delivering superior edge finishes, stable dimensions, reduced need for hard tooling, and fast setup times, helping clients achieve cost savings and efficiency in custom part manufacturing.

Branch Manufacturing Company, based in North Branch, Minnesota, specializes in precision engineering and manufacturing services, including mechanical metal stamping for a variety of metal parts. With a robust press room featuring up to 600 tons of capacity and advanced equipment like a 750-ton straightside draw press, the company excels in short- and long-run production, delivering fast, accurate stamping alongside complementary services such as tooling design, grinding, laser cutting, and sheet metal fabrication. As a partner in custom metal forming, Branch Manufacturing supports industries requiring high-quality, precise components through its CAD/CAM systems and inspection capabilities.

Branch Manufacturing, based in North Branch, Minnesota, provides comprehensive sheet metal forming and fabrication services as part of its in-house manufacturing capabilities, serving clients from prototype development through full-scale production. Specializing in metal stamping with presses up to 600 tons, the company handles blanking, progressive tooling, and deep drawing up to 12 inches for materials like aluminum, stainless steel, and carbon steel, complemented by laser cutting for short-run parts with precise edges and dimensions. Their integrated CAD/CAM systems, grinding equipment, and advanced inspection tools ensure high accuracy and quality, making them a reliable partner for custom sheet metal projects across various industries.

Branch Manufacturing Company, a Minnesota-based firm established in 1952, specializes in sheet metal manufacturing as a service from its 66,000-square-foot facility north of the Twin Cities. The company offers a full spectrum of in-house services, including laser cutting for precise, die-free production of short-run parts up to 1/4-inch thick on 48x96-inch sheets, metal stamping with up to 600-ton press capacity for blanking and progressive tooling, and drawn parts up to 12 inches deep. Supported by advanced CAD/CAM systems, precision grinding, and inspection tools ensuring accuracy within microns, Branch Manufacturing combines innovative technology with personalized service to deliver efficient, high-quality solutions for prototype through production runs.

Branch Manufacturing, a Minnesota-based company established in 1952, specializes in a variety of precision manufacturing services from its 66,000-square-foot facility, including CAD/CAM design, grinding, laser cutting, metal stamping and drawn parts, sheet metal fabrication, and precision inspection to ensure high-quality outcomes for clients across industries. However, based on available company profiles and service listings, Branch Manufacturing does not explicitly offer sheet metal roll forming as a dedicated service, focusing instead on stamping, fabrication, and related processes; potential clients interested in roll forming may need to contact them directly for custom capabilities or explore specialized providers in that area.

Branch Manufacturing specializes in Tool & Die Engineering and Manufacturing, delivering precision-crafted solutions for diverse industries. With a focus on quality and innovation, their expert team designs and produces custom tools, dies, and components tailored to client specifications. Utilizing advanced technology and rigorous quality control, Branch Manufacturing ensures durability, accuracy, and efficiency in every project, supporting applications from automotive to aerospace. Their commitment to excellence and customer satisfaction makes them a trusted partner for businesses seeking reliable, high-performance tooling solutions.